As reservoir development moves into more geologically complex settings, fracture design and analysis continue to be essential for reliable stimulation outcomes. These tools enable teams to plan treatments that account for formation variability, improve execution in real time, and evaluate performance post-job to guide future designs.

Anticipating Subsurface Behavior

Fracture models provide a window into how a treatment might unfold under specific geomechanical and operational conditions. Engineers consider:

- Key factors like in-situ stress, fluid viscosity, proppant transport, and natural fracture networks

- Anticipated fracture length, height growth, and geometry before pumping begins

- Formation challenges such as stress anisotropy, weak rock, or high leak-off potential

- Decisions on staging, perforation strategy, pad volume, and proppant type to fit local conditions

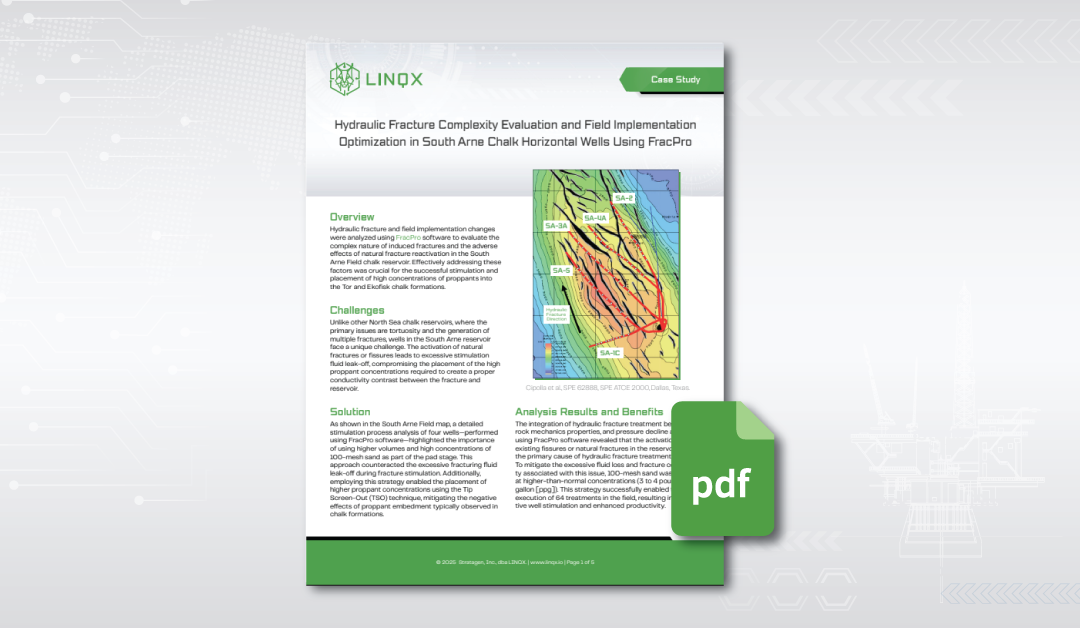

A recent example of this approach in a chalk reservoir can be found in the South Arne Field case study, where fracture design adjustments led to improved proppant placement and overall stimulation success.

Read the full case study here.

Common Challenges in Fracture Design Execution

Monitoring treatment pressure, rate changes, and proppant concentration in real time allows engineers to compare modeled expectations with actual behavior. When deviations occur—such as early screen-out, excessive pressure build-up, or poor proppant placement—teams can adjust operations and record those outcomes to inform future wells.

After the job, pressure falloff analysis and production performance data can be used to validate or recalibrate the original fracture model, helping to close the loop between planning and field execution.

Connecting Execution to Design

Monitoring treatment pressure, rate changes, and proppant concentration in real time allows engineers to compare modeled expectations with actual behavior. When deviations occur—such as early screen-out, excessive pressure build-up, or poor proppant placement—teams can adjust operations and record those outcomes to inform future wells.

After the job, pressure falloff analysis and production performance data can be used to validate or recalibrate the original fracture model, helping to close the loop between planning and field execution.

Application in Complex Reservoirs

Challenging formations such as chalk, where natural fractures and weak rock contribute to high fluid loss or proppant embedment, require detailed analysis to guide treatment design. In these settings, modeling often informs the use of finer mesh proppant, higher pad concentrations, or fracture containment strategies to improve stimulation effectiveness.

Driving Better Stimulation Results Through Design Insight

Understanding how treatment parameters interact with formation characteristics is key to improving stimulation success—especially in reservoirs where complexity, natural fractures, or fluid loss can limit proppant placement. Tools like FracPro help engineers evaluate these conditions in advance, monitor job performance, and fine-tune future designs. To learn how FracPro supports more effective, insight-driven fracture design across planning, execution, and evaluation, connect with our team.