If you’ve planned or executed a well in today’s increasingly complex drilling environments, you know success isn’t defined only by reaching total depth. It’s about everything leading up to it—anticipating variables, engineering precision into every phase, and minimizing uncertainty before the first bit turns.

For many engineers, the question isn’t if problems will arise—but how well they’re prepared to handle them. That preparation begins with accurate modeling, dynamic simulation, and the ability to visualize what’s happening downhole before it actually happens.

Understanding Cement Behavior in Complex Displacement Environments

Cementing decisions made early in the design stage can determine whether long-term zonal isolation succeeds—or fails. Even when centralizers are run and volumes are calculated, small oversights can lead to uneven displacement, fluid channeling, or thermal expansion issues downhole.

If you’ve ever looked at a post-job evaluation and thought, “We should’ve caught that earlier,” you’re not alone.

That’s where advanced simulation tools come in. These tools should support:

- Modeling of multi-string casing configurations and centralizer placement

- Evaluation of displacement paths with temperature and compressibility effects

- Prediction of mud removal efficiency and interface stability

- Visualization of flow behavior during spacer and slurry placement

With these capabilities, engineers can validate their designs and reduce uncertainty before operations begin.

Analyzing Torque and Drag in Extended and High-Angle Wells

In extended-reach or high-angle wells, torque and drag don’t behave the way they do on paper. Loads shift, contact points move, and buckling becomes more likely as geometry changes. It’s no longer just about clearance—it’s about how dynamic the system becomes once drilling starts.

If you’ve encountered unplanned loads, stuck pipe events, or poor hole cleaning mid-run, you know how quickly margins can disappear.

To stay ahead of these challenges, mechanical modeling environments should include:

- Real-time torque and drag prediction along complex trajectories

- Buckling analysis (sinusoidal and helical) under dynamic loading

- Surge and swab pressure modeling during tripping and circulation

- Equivalent circulating density (ECD) tracking for hydraulics optimization

These features allow engineers to evaluate operational limits and plan accordingly under realistic mechanical loads.

Evaluating Drilling Fluid Behavior and Streamlining Mud Reporting

Drilling fluids do more than carry cuttings—they stabilize the borehole, maintain pressure, and react to every operational change. But when reporting is slow or disconnected from real-time systems, even the most experienced teams may find themselves reacting too late.

If you’ve ever reviewed a mud report and wished for earlier, clearer indicators of trouble, you’re not alone.

Modern mud systems should offer:

- Automated analysis of solids content, rheology, and additive performance

- Integration with rig sensors for real-time fluid behavior monitoring

- Material tracking for accurate inventory and loss reporting

- Standardized, customizable reporting formats for engineering review

These capabilities enhance decision-making and improve communication across the drilling team. To explore more about well construction software solutions and their technical applications, visit our website.

Building Smarter Wells Starts with Smarter Modeling

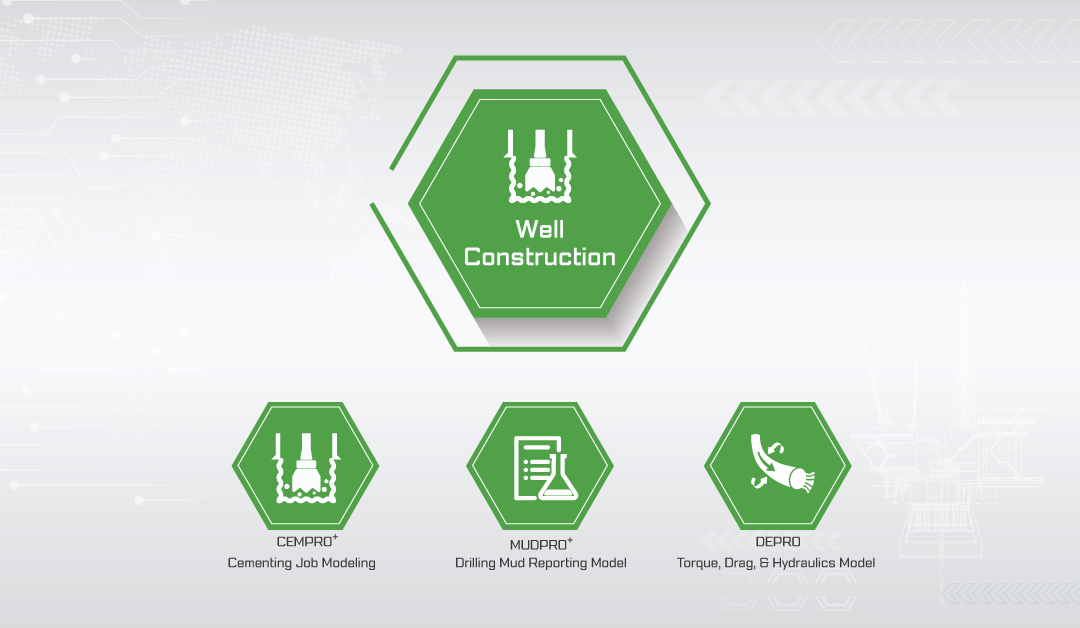

Each of these well construction domains—cement placement, torque and drag, hydraulics, and mud reporting—shares a common theme: when engineers can accurately model real-world conditions early, they gain the clarity needed to anticipate challenges before they arise. That foresight translates into stronger planning, more confident execution, and more efficient wells overall.

If you’re navigating similar technical challenges in your operations, we invite you to connect with us at the 2025 Offshore Technology Conference, taking place May 5–8 in Houston, Texas, at NRG Park. Our team will be showcasing simulation and modeling tools designed to support data-driven decisions across the entire well construction process. Whether you’re attending the event or exploring solutions remotely, we welcome the opportunity to talk. Visit our booth to see the technology in action—or to our team to learn more.